1. material requests

1.1 How do I activate indirect warehouse management?

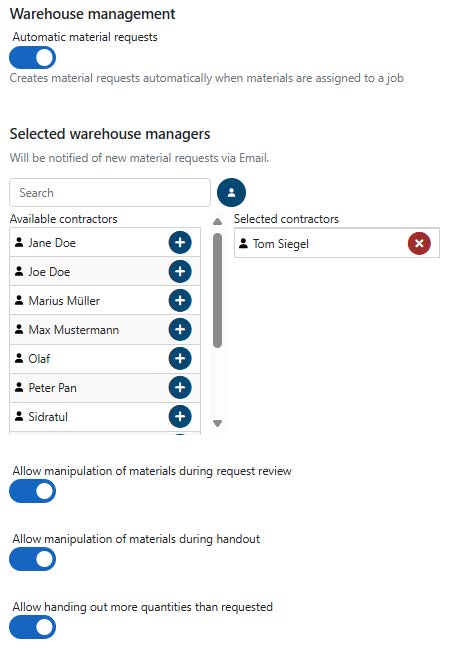

1.2 Warehouse manager

1.3 Configuration

You have 3 options for controlling indirect warehouse management.

- Allow manipulation of materials during the request review.

If this function is activated, the warehouse manager with the “CanReviewMaterialRequest” access role has the option of adjusting the requested materials before approval. This is useful if the warehouse manager can better estimate the quantities and materials actually required or if material requests are created with placeholder quantities. - Allow manipulation of materials during issue

If this function is activated, the warehouse manager with the “CanHandoutMaterials” access role can issue materials and quantities other than those defined in the original material request. This is useful for correcting minor errors within a request. - Allow the issue of more materials than requested

If this option is activated, the warehouse manager with the “CanHandoutMaterials” access role can issue larger quantities than originally defined in the material request. In contrast to the previous option, however, no additional materials can be issued here.

1.4 How does indirect warehouse management work?

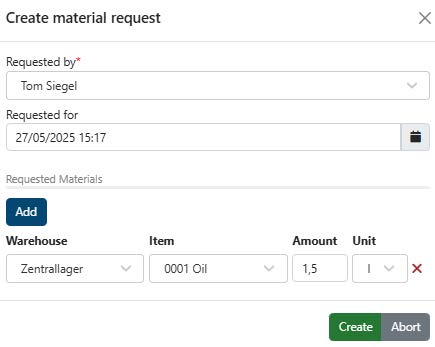

1.4.1 What does a material request consist of?

A material request includes the following properties:

- the person who needs the materials,

- the time at which the materials are required.

- the requested materials.

1.4.2 What happens with a material request?

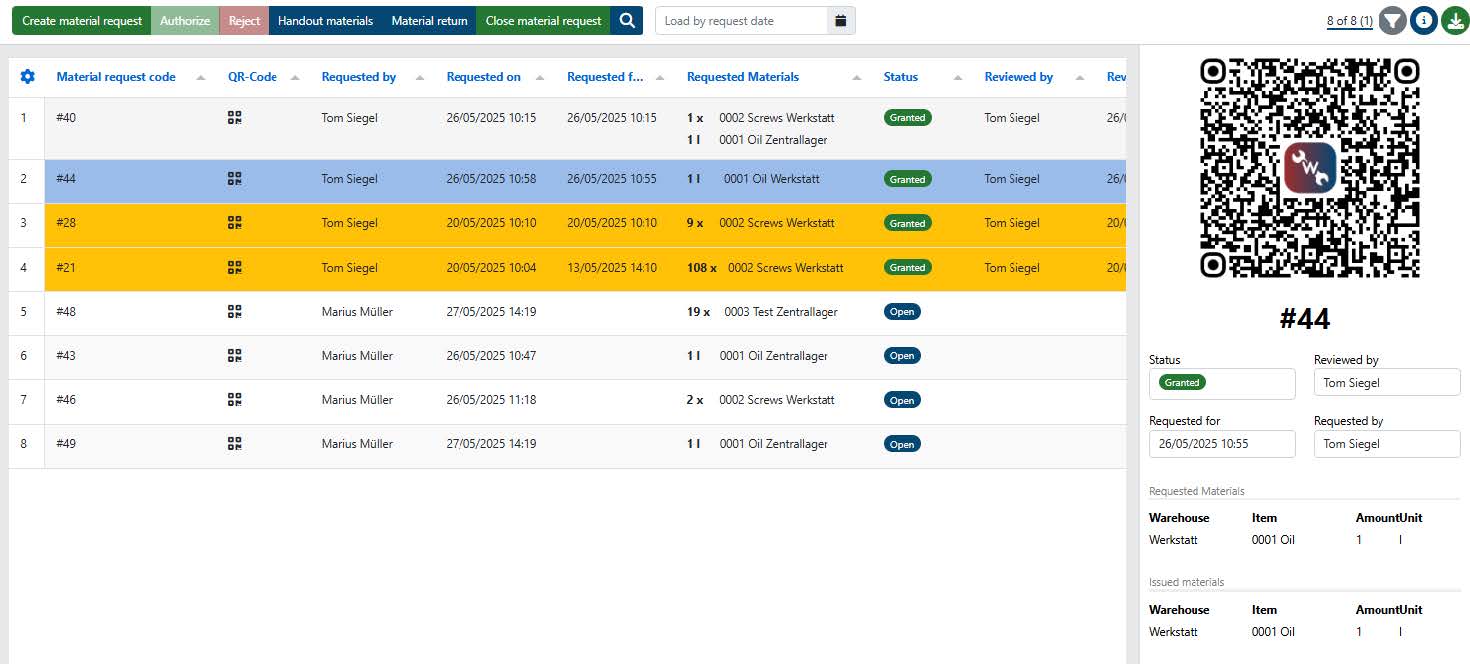

Every material request goes through the following process:

- Make a request

- Review

– Approval (step 3 is executed)

– Rejection (request completed) - Publication of materials

- Return of materials

- Completion of the material request

Once a material request has been created, it is either confirmed or rejected by a warehouse manager with the “CanReviewMaterialRequest” access role.

If a material request is rejected, the employee who made the request is informed. The request is then closed and will not be processed any further. If a warehouse manager has made a mistake during the check, they can still confirm the rejected request at a later date.

Once a material request has been confirmed, the warehouse manager with the “CanHandoutMaterials” access role can issue materials to consumers in the next step. Options 2 and 3 in the Configuration chapter play an important role here.

After the materials have been issued, consumers can return the remaining quantity. Using the material return function, the warehouse manager with the “CanHandoutMaterials” access role receives the materials and returns them to the system accordingly.

When goods are issued and returned, appropriate stock movements are created in the relevant warehouses in order to keep stock levels up to date at all times.

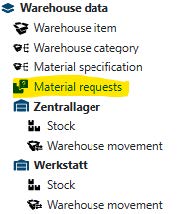

All actions can be carried out via the “Material requests” page, provided the user has the appropriate authorization. It offers both a user-specific overview of all requests and the option to manage them.

1.5 App integration

1.5.1 Storage functions

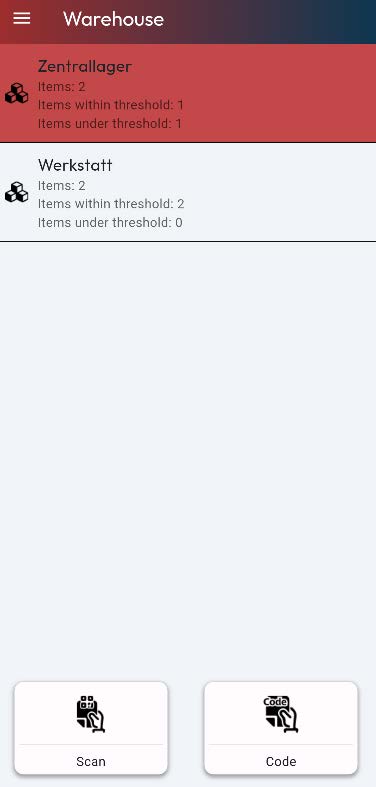

All warehouse functions can be found under the new “Warehouse” tab.

You can use the warehouse page to get an overview of the stock of all available warehouses and process material requests.

Use the “Scan” or “Code” buttons to open a material request and perform the corresponding actions.

1.5.2 QR codes

QR codes are used to speed up the processing of requests. Simply scan the QR code of an employee asking for materials to confirm the request on the spot and issue or return materials.

2. service overview

3. order templates

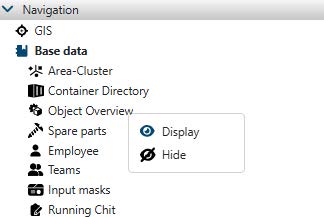

4. show and hide navigation entries

5. sort group contents

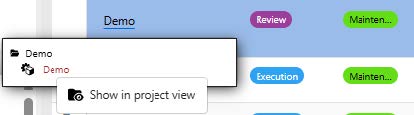

6. display object in the project view

7. notification of changes in tables

8. new reactions for object and routing slip

- Perform maintenance

- Carry out repair

- Perform task.

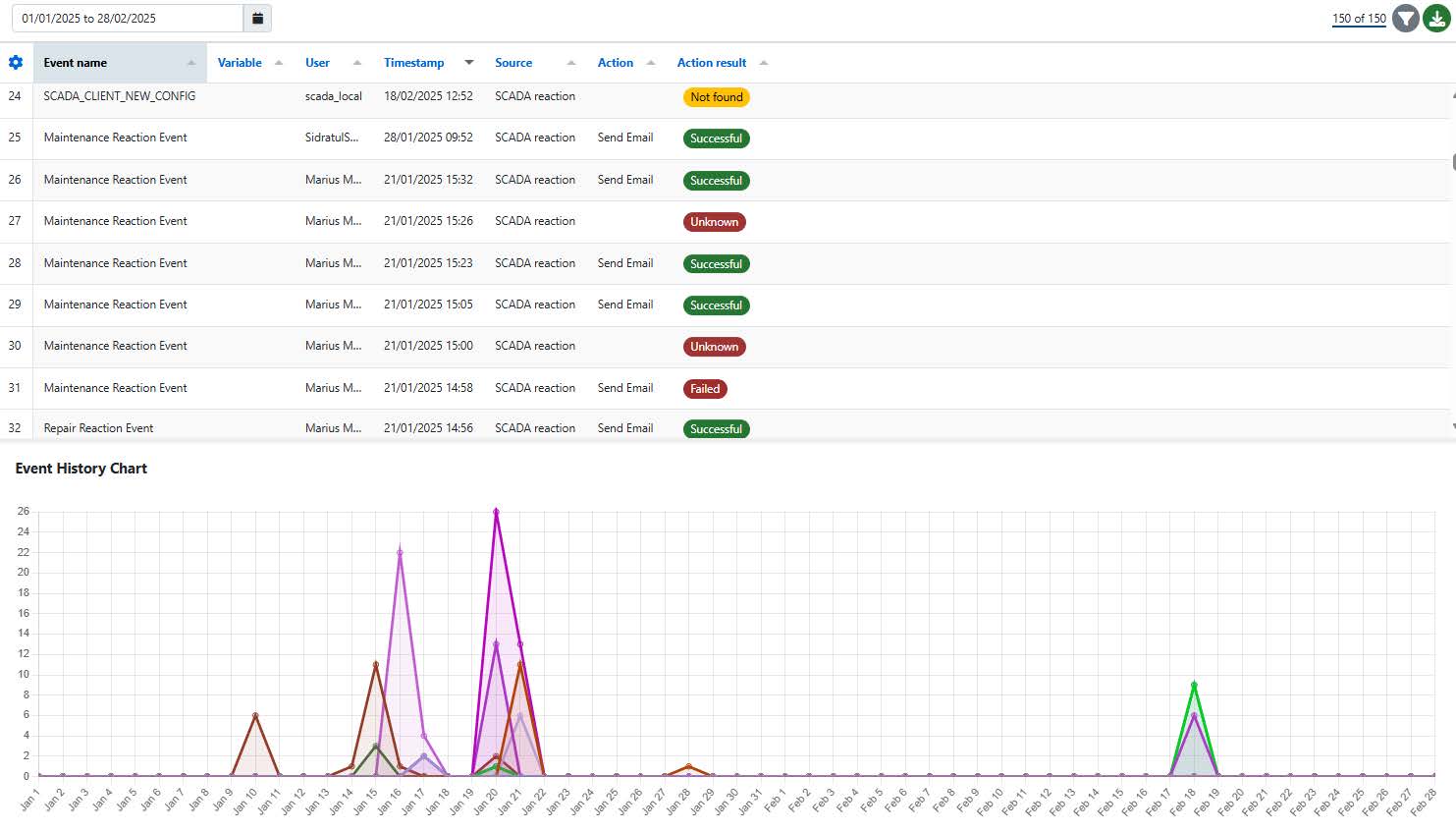

9. event history statistics

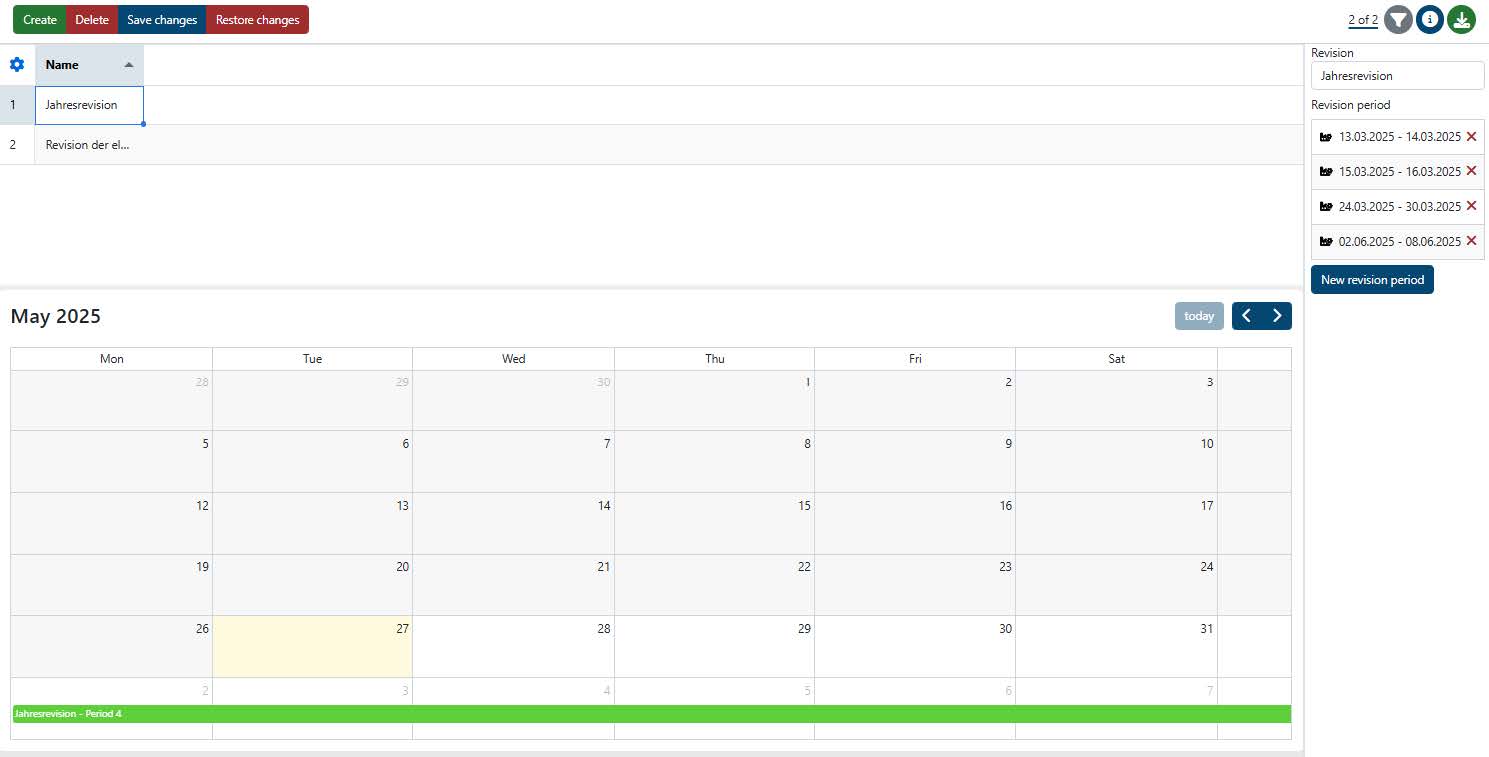

10. revisions

10.1 “Revision” service parameter

The “Revision” service parameter is now available in the service configuration. This allows you to assign a service to a specific revision and make it available in the planning overview for all revision periods.

10.2 Overview of revisions

The Revisions page gives you an overview:

- Table of all revisions

Clearly displays all revisions in a table. The various revision periods can be defined here for the individual revision plans. - Calendar display

Graphic overview of all revision periods throughout the year.

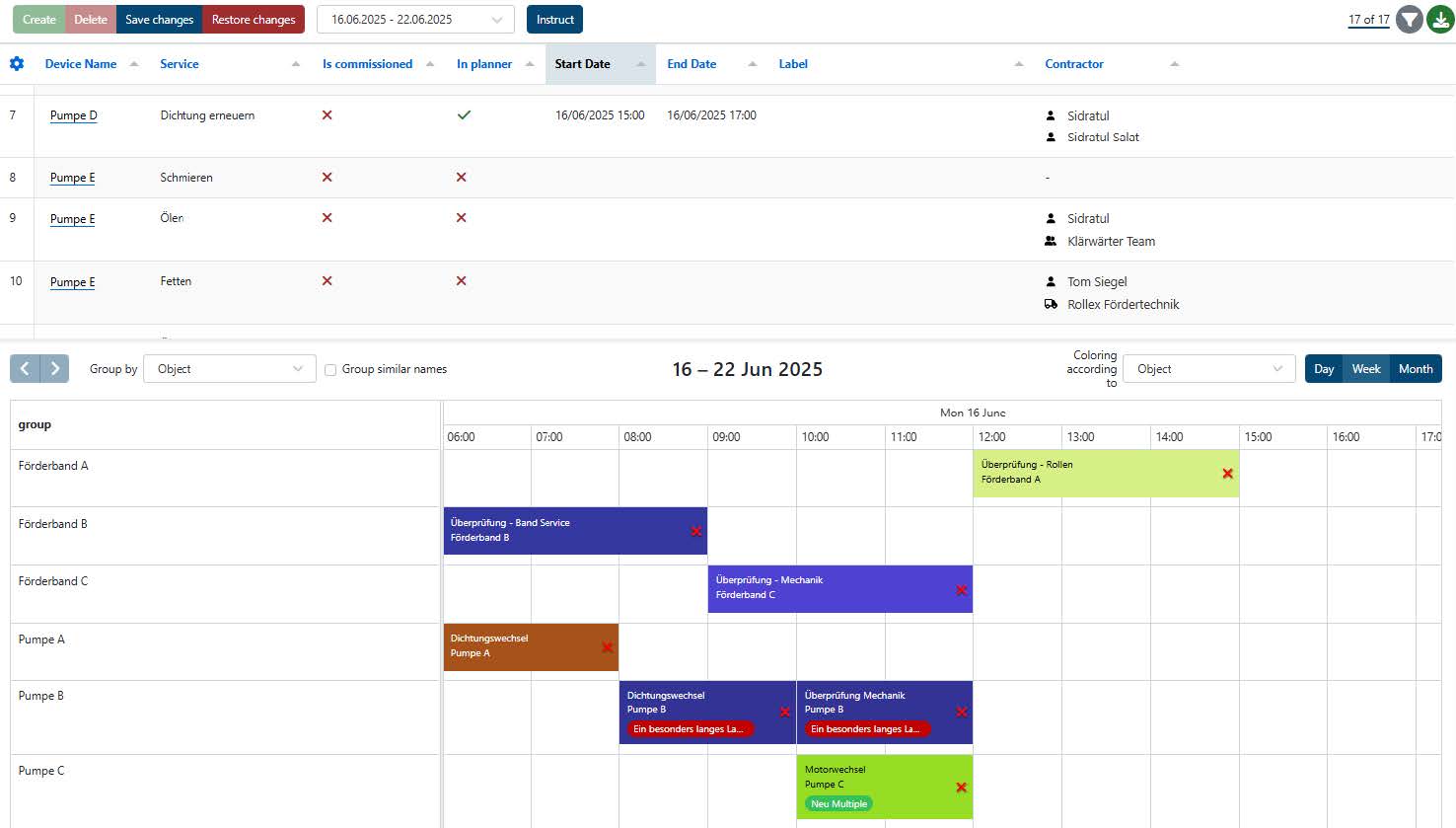

10.3 Plan revision

There is a revision planner for each revision created, on which there are two areas:

- Service list

Shows all services that have been assigned to the revision via the Revision parameter. - Planning calendar

Visualizes all planned services flexibly and graphically appealing.

– Allows you to drag and drop services from the table to the desired time

– Within the calendar, entries can be grouped according to various criteria (e.g. object type, manufacturer, etc.) and highlighted in color.

– The calendar entries can be moved, adjusted and removed directly in the calendar for easy planning.

– Contractors are assigned from the responsible persons and can be customized for easy creation of orders.

10.4 Orders from an audit period

After planning the individual services in the calendar or table, you can generate orders via the known and revised order window for object monitoring.

11. labels for notes

12 Further changes

- Images can now be attached when creating a repair or maintenance.

- Simplification of the commissioning of services in property monitoring through a revised user interface and more detailed error messages.

13. bug fixes

- Error when loading services without active service parameters

- Permanent blocking of events that are sent more frequently than the request limit allows.

- Error when loading object filters with more than 1,000 objects as a result

- Error when caching the project view after moving and deleting entries

- Error when saving if only the object within a task was edited.

- Error when changing a yes/no field in Microsoft Edge

- Error when showing and hiding columns

- Error when displaying recently deleted faults on the fault page if a time period was selected.

- Error when deleting routing slip fields

- Incorrect formatting of the language column when exporting the employee table

- Error when deleting a connection between employee and team from the Teams page

- Error when editing an object that is linked to a deleted manufacturer or object type.

- Incorrect behavior of text fields in tables

- Error when loading stock movements over the period on the stock movement page.

- The end date of maintenance can no longer be in the future (later than tonight).

- Translations have been added to the settings page.

- Validation of whether an order number has already been assigned, with notification to the user

- Validation of the maximum possible length of a name for a label

- Message when a user attempts to delete a completed training course.

- Updating the contractor list in the event of changes to employees, teams, manufacturers or subcontractors

- The profile picture of an object is now also transferred when duplicating.

- Rename the “Create” actions in the windows for “Maintenance”, “Repair”, “Replacement” and “Task” from “Create” to “Complete”.

- Correct validation of the order status when processing an order

- All mandatory fields are now also marked as such

- Inactive service parameters are no longer listed in object monitoring

App

- Error when selecting the service during a quick maintenance if the object is selected from the tree view.

- Endless loading screen if incorrect login details are entered.

- Message in the event of incorrect entries during maintenance.